Talk to us about your tensile testing requirements and we can arrange a solution demo with tensile testing of your samples.

Tensile testing is an important part of design and quality control for ensuring product safety and performance. PPT Group can guide you to the best solution for your tensile testing requirements.

Tensile testing has long been an import part of design and quality control for ensuring product safety and performance. It is also an essential part of the testing regime which helps deliver cost-effective consistency and efficiency in manufacturing and assembly.

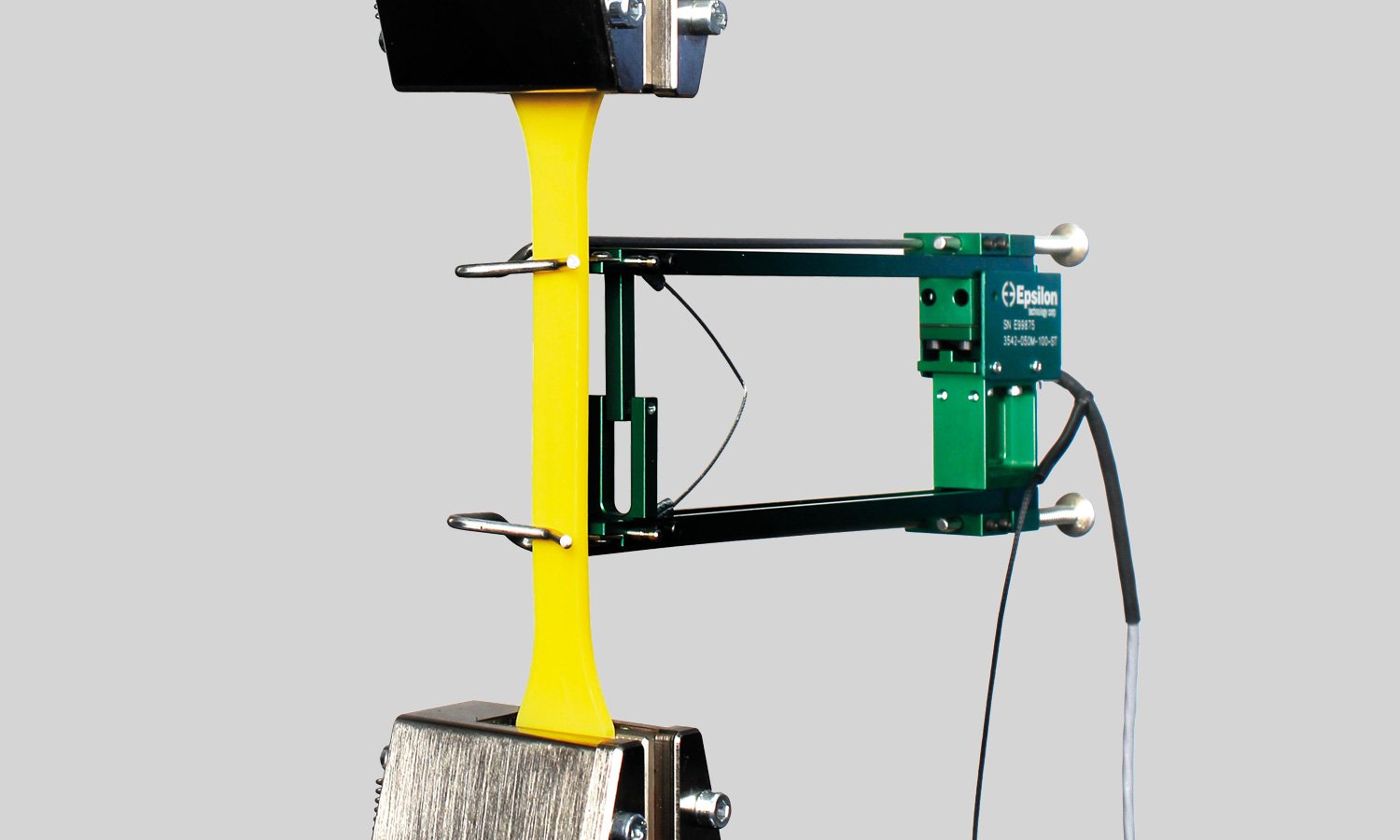

Tensile testing is commonly understood as 'the application of a uni-axial tension force to measure the performance of a test sample, up to the point it yields or breaks'. Basically it involves pulling something apart in a straight line and seeing how its physical properties change.

There are literally millions of components used in assemblies and finished products that rely on their physical strength properties for their success. If they are too weak they will quickly fail, rendering the finished product useless. If they are too strong they may not even function properly.

Each component has a vital part to play and is batch-tested for its tensile strength to make sure it meets strict quality specifications before it is assembled into the finished product.